News

Before You Buy: Considerations for Upgrading and Replacing Terminal Hardware

BEFORE YOU BUY: Considerations for Upgrading and Replacing Terminal Hardware

Equipment breakdowns are part of daily life on marine and rail terminals, as is purchasing and installing new terminal hardware to replace outdated and defunct equipment. Procurement managers purchasing equipment are often faced with an all-too-common scenario: take all equipment training, maintenance, and repairs in-house or feel locked into a vendor-specific support agreement when purchasing that equipment.

It’s only later—often a few months after declining offers of additional ongoing vendor support—that they return to the vendor in search of faster, cheaper, and more consistent support than what their in-house professionals or hardware-specific vendors can provide.

“When you add maintenance and repair to the workload of in-house technicians, you end up pulling resources away from core operations,” says David Fajardo, Manager of Field Technical Services at Buckeye Mountain. “Suddenly, there’s a man-hour cost to fixing hardware on top of the operational cost of equipment downtime—which turns every small problem into a five-alarm fire.”

The difficulty of maintaining equipment internally only increases over time. Terminal operating systems are becoming more intelligent and more complex—so is the new equipment deployed on the terminal. As a result, maintaining and repairing this equipment has become a heavier lift, increasing the strain placed on in-house technicians.

Buckeye Mountain’s field technical support services are designed to alleviate this burden, freeing up in-house technicians and resources to focus on supporting the terminal’s core operations. Terminal managers can coordinate planned, strategic equipment updates that prevent resource exhaustion and operational downtime by outsourcing equipment maintenance and repair to a trusted partner.

Read on to find out how our “boots on the ground” approach can help improve equipment availability and long-term value at your terminal while supporting better distribution, logistics, and other operational efficiencies for your customers.

Understanding the Strategy Behind Purchasing the Hardware

Purchasing the right hardware is only part of a successful procurement process. Before that purchase, procurement leaders face several strategic decisions that will affect the performance and value of that equipment throughout its lifespan.

By making these decisions ahead of your purchase, procurement managers can work with field operations leaders to determine the best approach for managing the equipment’s maintenance, repairs, asset management needs, and technical support.

Maintenance Plan and Warranty

Maintenance plans and equipment warranties help set the foundation for the long-term value you create from your hardware investment.

Warranties protect your company if your new equipment doesn’t meet quality assurance expectations. Meanwhile, a robust maintenance plan is critical to ensuring hardware receives preventative maintenance that reduces equipment failures and operational downtime.

“With almost any hardware installation we perform, we try to set up some sort of preventative maintenance plan,” says Fajardo. “You always want to correct issues before they become a problem.”

Before purchasing your hardware, find out if preventative maintenance is included in the purchase to maximize the longevity and reliability of your asset. Review your warranty carefully to understand the type of coverage you can expect if problems arise within the warranty period.

Asset Management

A comprehensive asset management strategy is critical to tracking hardware maintenance and servicing across the asset lifecycle. This is particularly important for terminals tracking many pieces of hardware facing unique maintenance needs and different stages of their lifecycles.

Whether your on-site field operations team or a third-party service provider handles your asset management, ensure you have a clear plan for managing new hardware purchases alongside your existing technology.

Regular hardware auditing should be a subset of your asset management strategy. Hardware auditing helps you track physical assets that you may reallocate within the terminal, and it supports preventative maintenance by making sure upcoming parts replacements and other asset management tasks are performed on schedule.

These audits are necessary to confirm that all equipment operating at your terminal is still meeting expectations regarding performance, efficiency, and any applicable compliance requirements.

Configuration and Repairs

Routine configuration of equipment ensures that your hardware is optimized for peak performance. Hardware relocated or utilized for a new purpose may need to be configured to its new environment and requirements.

Hardware configuration and repairs can disrupt your terminal’s work environment. Strategic planning is needed to coordinate repairs and servicing so that operations experience minimal disruption, if any.

Terminals tasking hardware configuration and repairs to in-house technicians may face a greater risk of disruption due to limited labor and resource flexibility: since in-house technicians are juggling hardware repairs alongside a laundry list of other responsibilities, they may not have the luxury of scheduling repairs during periods of non-peak workloads for the facility. Disrupted operations can increase material costs for your customers and the facility itself.

Tech Support and Downtime

Equipment failures and other hardware issues can have a disastrous impact on terminal operations, resulting in significant outages that bring operations to a halt and cost the facility—and its customers—revenue.

When technical issues arise, a single in-house technician often needs more resources and bandwidth to quickly resolve the issue, leading to extended downtime and mounting financial losses. Professional support services, like Buckeye Mountain, on the other hand, are better equipped to respond with multiple technicians in the field who can quickly resolve the issue and bring your equipment back online.

“Technical issues can be a daily occurrence at some terminals, and many of these issues must be addressed manually by on-site technicians,” says Fajardo. “Since Buckeye knows how to install this hardware correctly, though, we’re able to reduce the frequency of these issues—and if something goes wrong, we’re right there to help.”

Accounting for Long-term Cost vs. Long-term Value

Equipment costs don’t end when you purchase your new hardware. But, the expense incurred over that equipment’s lifespan depends on your strategy for handling maintenance and repairs, minimizing equipment downtime, and maximizing the lifespan of your assets.

Higher costs don’t always result in less value for your investment. With equipment servicing, the opposite is often true: proactive spending for preventative maintenance and repair can substantially increase potential value creation from your equipment.

Procurement managers can help optimize costs and maximize long-term value potential by setting up an equipment servicing plan that prioritizes cost-efficient spending and long-term equipment health.

Increasing Longevity while reducing downtime

Equipment upgrades and replacements deliver an immediate impact to terminal operations. Even for procurement managers, it’s easy to get stuck on those short-term gains and overlook the long-term implications of that hardware investment.

In the end, though, the overall value each asset delivers for your organization will be determined by its longevity, long-term costs, and performance across the equipment lifecycle. Your equipment servicing plan directly affects each of these success metrics.

“It’s just like your car: If you take care of it, it’s going to last longer,” Fajardo says. “We’re like the mechanic working on your car: We keep the equipment well-maintained so that terminal operators get more longevity from each asset—and, in turn, get a better return on their hardware investment.”

According to Fajardo, this approach has enabled Buckeye Mountain to add years to the lifecycle of the customer equipment it manages. Thanks to Buckeye’s proactive maintenance, companies hoping to get five years of service out of a single asset regularly enjoy seven or eight years of service from that equipment.

The Impact of Repairs, Support, and Maintenance on Capital Budgets

Poor asset management practices can lead to inconsistent and delayed equipment maintenance, along with an increase in preventable repairs. These inefficiencies can result in budget overruns that leave your operations team with broken equipment and no room left in the budget for repairs.

In-house asset management can increase your organization’s exposure to these increased costs—especially if asset management is handled on a case-by-case basis when something needs repair. Since in-house technicians must juggle equipment maintenance and repair, among other tasks, costly delays are all but inevitable.

“We had one customer who moved away from our ‘boots-on-the-ground’ approach to bring asset management in-house and save on equipment servicing costs,” says Fajardo. “They quickly realized they lost a lot of asset management expertise that Buckeye Mountain brings to the table. We do things beyond scope to ensure our customers are taken care of—and we have an internal structure for managing assets that other companies can’t match.”

How Buckeye Mountain Adds Value

Outsourced equipment servicing not only helps you control hardware costs but also reduces the burden placed on in-house technicians.

It also allows your terminal to leverage the expertise of a service partner who can manage the entire equipment lifecycle for all of your assets—and do it better, more efficiently, and cheaper than your business could on its own.

When you choose Buckeye Mountain as your equipment service provider, you can expect the following:

Comprehensive Services

Buckeye Mountain is a value-added reseller across the rail, intermodal, and port industries. We offer competitive pricing and services tailored to your terminal’s unique needs.

When you contract with us as your equipment service provider, we work with you to develop a service plan that meets and exceeds your organization’s expectations. We go above and beyond our scope to deliver a turnkey solution that is flexible to your needs.

End-to-end Support

From product sourcing to lifecycle management, our service support covers equipment installation, training, maintenance, repair, and replacement—all to extend hardware lifespans, minimize operational disruptions, and maximize the value of your equipment investment.

Continuous Maintenance and Rapid Response

We quickly deploy a boots-on-the-ground presence when maintenance and repair services are required.

Our ongoing, on-site support provides continuous coverage for the full spectrum of equipment servicing needs, including rapid replacements and hardware upgrades to minimize downtime and ensure operational continuity.

Support Subscriptions for Managed Services

Expand your Buckeye Mountain service relationship by adding subscription options for 24/7 support. Our managed services can be configured to your facility’s unique needs, including remote and in-person support options.

We also offer coverage for a wide range of service needs, including network maintenance and equipment training.

Get the Most from Our Equipment Investment

Upgrading and replacing terminal hardware isn’t cheap. But if you don’t properly manage and maintain this new equipment, your long-term costs will soar—and the value of these assets will continue to decline until they reach the end of their lifecycle.

Buckeye Mountain can help you avoid this outcome. We provide a boots-on-the-ground presence to support your equipment across its lifespan, improving its longevity and availability while lowering costs and freeing up in-house resources.

Invest in your equipment by investing in Buckeye Mountain’s expertise.

Rapid Deploy Wi-Fi Buyer’s Guide

Rapid Deploy Wi-Fi Buyer’s Guide

The best wireless communications infrastructure should be designed specifically for the environment where it’s deployed.

But what happens when that environment drops a few thousand tons of corrugated steel in the path of your hotspot?

That’s exactly the challenge faced by rail yards and marine terminals. One day, your mobile devices will have clear lines of sight to the access points supporting local communications. The next day, shipping containers formed a 60-foot-tall wall, blocking that pathway and resulting in a poor or lost signal. And that’s only one problem plaguing transportation companies’ wireless connectivity.

“Managing connectivity in an outdoor environment is understood to be different than an office building or a home – but managing an ever changing outdoor environment creates even more of a challenge. You aren’t just monitoring uptime and downtime; it’s managing the infrastructure and coverage, high amounts of noise, and detours in network paths – all of which Rapid Deploy has engineered and designed. Redundancy is the backbone of Rapid Deploy. Whether it’s power or signal, we’ve built this to withstand the harshest environments.”

— Alex Wright, Regional Sales Director, Buckeye Mountain

Wireless connectivity is a crucial, though often challenging, infrastructure component for rail, intermodal, and marine operations. Reliable and managed connectivity powers the essential technology in these environments. However, the current approach has fallen short of providing operators with the necessary technology, expertise, and support to establish and maintain consistent Wi-Fi coverage. And as many rail and marine yard operational leaders already know, the convenience of LTE and private LTE connectivity comes with stark limitations of its own.

So Buckeye Mountain developed our Rapid Deploy family of products to be the partner that operators need.

In this buyer’s guide, we aim to:

- Identify the top problems affecting wireless connectivity in today’s rail, intermodal, and marine environments.

- Explain how our family of Rapid Deploy products can help your operations overcome these limitations.

- Show how our patented approach allows for faster, cheaper deployments than alternative infrastructure solutions.

- Get you started with some key questions to ask as you approach the task of reconfiguring wireless connectivity in your yard.

Today, Buckeye Mountain is a leading provider of end-to-end solutions for the intermodal and rail industries, providing rugged hardware, customized software, wireless network infrastructure, and robust tech support and operations consulting to rail and intermodal yards around the country.

In the past, all of these challenges were compounded with the lack of support of resource management software and solutions to alleviate this manual burden.

The unique challenges of improving connectivity in the yard

Outdoor environments are challenging in their own right. But even within the transportation space, the specific difficulties facing Wi-Fi connectivity can vary from one location to the next.

Differences in the physical space, types of shipping and transport taking place in those environments, existing infrastructure already in place, and operations personnel themselves can all affect not only the problems facing Wi-Fi communications, but also which technology might offer the best solution.

Here are the most pervasive obstacles to improved Wi-Fi connectivity:

The Physical Landscape is Constantly Shifting

In both rail yards and marine terminals, heavy lift equipment will often take steel containers that are constantly being unloaded, stacked, relocated, and loaded for shipping, and cause dramatic changes to the landscape of the environment.

As a result, Wi-Fi and LTE signals end up bouncing off containers enroute to their destination, resulting in degraded communications and, in some cases, signal loss. The ever-changing landscape and height of these container stacks make it impossible to reliably plan traditional Wi-Fi infrastructure that is able to reach all parts of the yard at all times.

On-the-Ground Personnel Lack RF Expertise

Networking engineers are present at many rail yards and marine terminals to help address networking challenges that might arise.

While these engineers may have some familiarity with wireless networking, collaborating with them provides an opportunity to share deeper knowledge of radio waves and RF engineering. By working together and providing accessible training, we can add extensive expertise to better understand how the environment impacts communications and effectively address any Wi-Fi connectivity challenges.

A Consistent Power Supply is Essential for Wi-Fi Devices

Routers, switches, and other Wi-Fi devices are often slow to reboot after a power outage, extending the Wi-Fi network’s downtime as those devices return to normal operations. To maintain connectivity and support continued operations, Wi-Fi infrastructure needs to be supported with backup power supplies that can support devices through an extended outage.

“We’ve put a lot of effort into making sure that we have systems that have extensive backup times,” says Steve Hill, Director of Wireless Engineering at Buckeye Mountain. A typical backup power unit, he explains, is designed to run a server for only the time it takes to get the device properly shut down—not to last through an extended power outage.

“Our systems are designed to outlast power outages for 24 or 48 hours,” Steve shares. “In fact, we have systems out there right now that have gone seven years without an unplanned outage.”

Infrastructure Installation Can Be Costly and Complex

Conventional Wi-Fi infrastructure comes at a much higher cost than alternative connectivity solutions—and the installation of this infrastructure can be highly disruptive to day-to-day operations.

Even after this infrastructure is installed, the endpoint devices deployed can lead to signal loss and other service issues in a constantly changing outdoor environment. Properties investing in Wi-Fi infrastructure are paying for premium connectivity, but the hardware powering this connectivity isn’t configured to the unique needs of dynamic rail and marine terminals.

LTE’s Ease of Use Isn’t All That It Seems

Rail and marine terminals have historically relied on cellular service providers because they are widely available and require no infrastructure installation. But LTE’s ease of adoption comes with the trade-off of suffering regular connectivity issues.

Compared to the high cost of installing conventional Wi-Fi infrastructure, those connectivity issues have often been viewed as the lesser of two evils. Still, the long-term opportunity cost of LTE has left rail and marine environments in desperate need of a more reliable connectivity solution.

Ongoing Maintenance is Required to Protect your Investment

The task of ensuring Wi-Fi connectivity doesn’t end when you install supportive devices in your outdoor environment. Continued maintenance and management are required to maximize network uptime, prolong the lifespan of devices, and realize cost efficiencies over time.

Rail and marine terminals either need to dedicate resources to this maintenance themselves or find a company that will provide ongoing support and service to their network.

Today’s options for wireless connectivity

No matter what provider you choose, or how they package their services and solutions, the wireless connectivity options available to rail yards and marine terminals fall into one of three categories: LTE, private LTE, or Wi-Fi.

Here’s an overview of each solution, including its strengths and weaknesses specific to the connectivity challenges of dynamic outdoor environments:

LTE Carriers

LTE/cellular carriers provide wireless connectivity over the same network used to serve individual consumers. Despite glaring limitations regarding its liability and throughput, LTE connectivity has been a popular option for larger terminals because of its accessibility and ease of deployment.

“LTE is a big competitor of ours right now, but it doesn’t solve a lot of the problems,” says Wright. “One of its biggest shortcomings is that it can’t support major uploads. Most terminal operating systems have upload requirements that exceed the capabilities of LTE.”

Says Hill: “Can LTE provide connectivity? Absolutely. Can it provide reasonable speeds? Absolutely. But is it reliable enough for your network? Can it provide the throughput that I’m going to need? No.”

Pros of LTE

- Reasonable speeds and connectivity

- No equipment installation required

Cons of LTE

- Not reliable enough for mission-critical workloads

- Can’t provide enough throughput to support rail and marine terminal operations

- Support from large cellular carriers will always be subpar given the time constraints of a container terminal or critical railyard.

- Inability to managed efficiently and effectively

Private LTE Network Equipment Providers

Private LTE uses the Citizens Broadband Radio Service to access unlicensed spectrum where individual entities can run their wireless communications across clean, available frequencies with little risk of interference. Equipment providers can give Intermodal yards the technology they need to set up their own “private” network for wireless connectivity, enjoying the connectivity and speeds of LTE while achieving reasonable throughputs.

But access to private spectrum comes with a catch. The FCC controls access to CBRS channels by dividing licensed providers into tiers. As a private LTE user, you’re a lower class of user than the larger wireless providers such as Verizon and AT&T—and if those higher-tier organizations need access to the spectrum you’re using, you could get kicked off.

“Before you access that spectrum, you have to go through a spectrum access system (SAS) administrator who confirms your identity and location and verifies that there’s an available CBRS channel for you to use,” says Hill. “If they give you the thumbs-up, off you go. But if a first or second-tier provider comes along and needs that channel, the SAS is going to drop you.

“So there’s an availability limitation, and a question of reliability, that comes with private LTE.”

Pros of private LTE:

- Access to clean frequencies

- Reasonable throughput

Cons of private LTE:

- Channel availability is not reliable

- Bandwidth limitation may not be sufficient for terminal operations

- Manage unplanned downtime due military presence, the highest tier of CBRs

Wi-Fi Service Providers

The wireless connectivity offered by Wi-Fi is unparalleled, delivering excellent availability, bandwidth, and throughput to support rail and marine operations at scale. But outdoor environments present a unique challenge when planning and deploying Wi-Fi infrastructure. Since most conventional Wi-Fi devices use omnidirectional antennas, they send and receive energy in every direction—even the wrong ones. In an outdoor setting, this can lead to high amounts of interference.

“In a hospital, you might have 500 or 1,000 access points,” Hill says. “But a hospital has walls, and the walls reduce the amount of signal spread, so you’re not going to have as much interference from all the access points that you would in the outdoor environment. But you can’t have 500 outdoor access points across the yard.”

Along with these logistical limitations, Wi-Fi service also comes at a premium cost: installing infrastructure is expensive and disruptive, and you could still suffer persistent connectivity issues despite your large investment.

Pros of Wi-Fi:

- High spectrum availability

- High bandwidth

- High potential throughput

Cons of Wi-Fi:

- Omnichannel antennas lead to increased interference in outdoor environments

- Wi-Fi signal from conventional access points weakens quickly with distance

- Poorly suited to a dynamic environment

- Conventional Wi-Fi installation costs are much higher than alternative solutions

Introducing: Autonomous Wireless Solutions (Rapid Deploy)

Unique problems require a unique solution. Rather than help rail and marine terminals get the most out of imperfect wireless connectivity solutions, Buckeye Mountain decided to create our own.

Thanks to this problem-solving approach, we’re proud to offer our customers a suite of autonomous wireless solutions supporting connectivity in any outdoor setting. Meet the Rapid Deploy family of products: our patented approach to deploying networks and delivering unparalleled performance in even the most challenging outdoor environments.

Our Rapid Deploy technology has been developed to serve various environments and use cases, ranging from fully standalone wireless networking to portable connectivity for emergency scenarios. Through these autonomous solutions, and with Buckeye Mountain’s ongoing support, rail and marine terminals finally have access to a comprehensive wireless connectivity solution resolving the pain points that have plagued their operations.

RapidOne

Designed for environments requiring a fully standalone wireless network, RapidOne is a solar-powered, self-contained networking solution that provides connectivity through an attached 20-foot mast. Devices are deployed in minutes or days and can operate in compact spaces, on gravel or hard surfaces, and amid exposure to extreme temperatures.

RapidOne systems can be deployed as a single, standalone unit, as a network of multiple units across a property, or as a supplement to existing wireless infrastructure.

RapidMiniMax

Turn existing structures and surfaces into supports for new wireless infrastructure. RapidMiniMax is a wireless networking solution that can attach to poles, towers, and other structures and surfaces to leverage existing vertical assets for improved wireless connectivity.

RapidMiniMax can run on existing AC power with a battery backup, or it can be configured to run exclusively on solar power. Like RapidOne, the RapidMiniMax can be quickly deployed in challenging environments and can function as a standalone solution or as part of an existing wireless infrastructure.

RapidCase

For on-the-go and remote situations, our RapidCase product is a compact, portable, network-in-a-box solution offering turnkey connectivity with the push of a button.

A portable, lightweight case contains everything you need to support Wi-Fi connectivity over a significant area, making RapidCase a critical tool for remote field work, emergency scenarios, search and rescue operations, and other planned and unplanned events. The case’s weatherproof design, extended battery life, and multiple backhaul options offer the flexibility and durability you need to support connectivity in the most challenging environments

RapidSky

Engineered to address the challenges of intermodal shipping and storage, RapidSky ensures reliable Wi-Fi coverage in shifting environments where high container stacks can create significant interference for other Wi-Fi networking technologies.

RapidSky uses light rings, or existing high mast lights, mounted 100 feet in the air to optimize signal patterns and connectivity, directing Wi-Fi signals toward the ground from an elevation that can overcome the stack interference common in marine and intermodal environments. (Not to mention you can run them on solar.)

RapidCrane

Designed for critical wide-span crane operations, RapidCrane offers high-speed, low-latency wireless connectivity that gives rail and marine crane operations the multi-gigabit speeds and redundant paths needed in this environment.

RapidFixed

Implement permanent wireless infrastructure through an installation requiring only a single augured hole. RapidFixed is a ground-anchored, elevated networking solution designed for deployment in environments with stacked intermodal containers.

With straightforward installation and the ability to scale your network with multiple RapidFixed units, this wireless connectivity product can be deployed in days while slashing your capital expenditures for installing and managing infrastructure. Access points are mounted on a mast that can reach 35 feet high for clearance above multi-container stacks in your yard.

RAPID DEPLOY IN ACTION: Customer Success Stories

With our family of Rapid Deploy products, we’re able to choose the right technology to address unique challenges facing our rail, intermodal, and marine customers.

“We have a patented very unique way of deploying, maintaining, and guaranteeing wireless connectivity inside of those very abusive environments,” says Greg Dunnell, Principal at Buckeye Mountain. “We solve the problems that others can’t because we live in those environments 100 percent of the time.”

Here are two success stories that began with a connectivity problem and ended with a Rapid Deploy solution:

Delivering reliable connectivity for an intermodal rail facility

The Problem:

Our intermodal rail customer was relying on an outdated narrowband solution to provide connectivity at their facility. But new applications desired by the company required high throughput and reliable connections unavailable through existing infrastructure and nearby cellular coverage.

Our Solution:

Buckeye’s Rapid Deploy team installed RapidFixed systems at nine of the company’s intermodal facilities. Thanks to the solution’s speed of delivery and operational impact, the company has continued to expand its use of RapidFixed systems at other intermodal facilities.

All locations using RapidFixed technology continue to be monitored and maintained through Buckeye Mountain’s connectivity-as-a-service model.

Ensuring Continuous Operations for a Maritime Port Facility

The Problem:

After deploying outdoor antenna systems to support wireless connectivity through local cellular service, one maritime port facility found that cellular connectivity couldn’t offer the reliability and performance required by its operations—especially in extreme weather conditions, and in an environment where containers could be stacked five high.

Our Solution:

Buckeye Mountain’s Rapid Deploy systems quickly demonstrated their value by maintaining wireless connectivity during a hurricane that struck the customer’s maritime port. Since then, the company running this port facility has relied on Buckeye to implement Rapid Deploy systems at four additional port facilities, as well as on two container ships.

MORE THAN TECHNOLOGY: The importance of working with technical experts

Investing in the right technology can put your wireless connectivity efforts on the right path forward. But to realize the performance and value of those solutions, you need ongoing support from technical experts who can plan deployments and provide continued remote monitoring and support.

That’s why expert-led support is a consistent point of emphasis at Buckeye Mountain. Our goal isn’t selling as many products as possible—it’s about ensuring continued customer success and satisfaction with the wireless connectivity we deliver.

Here’s how we achieve that goal:

Design and Installation Support

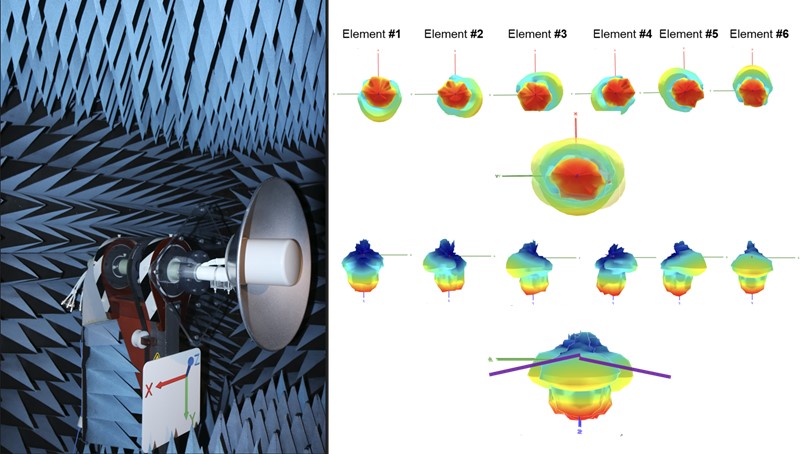

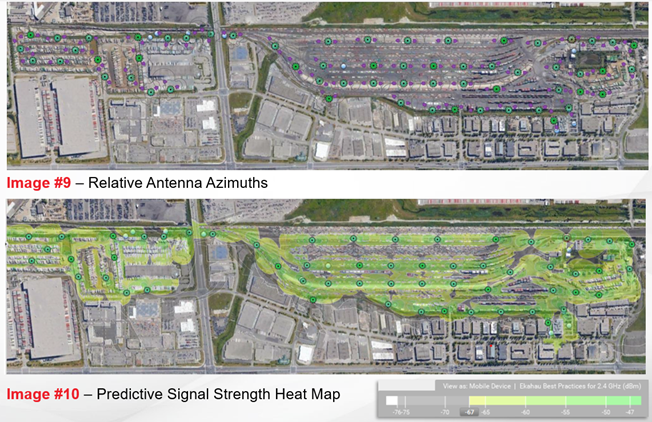

We use predictive studies, spectrum analysis, site surveys, and heat mapping to help plan a wireless infrastructure solution specific to your environment’s needs. Our design services are offered with the sole goal of fitting your facility with the right wireless products to maximize connectivity and your mobile experience.

Our installers ensure that all Rapid Deploy products are properly deployed, connected to power, and configured to support connectivity in your environment.

Ongoing Remote Management

Once your network infrastructure is live, our comprehensive remote management support monitors all conditions relevant to your Wi-Fi systems. Our remote management dashboard can track everything from throughput to system temperature to solar power energy yields and can notify your operations team or dispatch personnel if any equipment needs servicing.

Field Training and Operational Support

Achieving buy-in from on-the-ground operations personnel is a critical component of deploying new infrastructure solutions. Our in-house field technical services teams, composed of full-time employees, are experts at working with personnel to provide proper training, onboarding, and technical support that will maximize the value of your infrastructure investment.

“A big part of technical support is making sure that on-the-ground staff have confidence in the solution that they’re using,” says David Fajardo, Manager of Field Technical Services at Buckeye Mountain. “That means confidence on the training side, but also confidence that the solution is going to work every single time. If something’s not working, we need to be there to fix it.”

Key Questions to ask before Reconfiguring Wireless Connectivity in your Yard

Even with convenient, quick-deploy solutions like our Rapid Deploy products, upgrading your wireless infrastructure is a significant undertaking. Given the cost, complexity, and impact on operations, each facility must perform its due diligence before choosing a new approach to wireless connectivity.

As you approach this decision, here are some questions to ask any potential infrastructure solutions provider:

1. Why does this technology cost so much?

If you’re only anticipating the cost of the hardware itself, you might experience some sticker shock when faced with the full cost of new connectivity infrastructure. That’s because hardware is only part of the total package: facilities may also need solar power and battery solutions, mobile products, and ongoing support from the provider—not to mention regular maintenance to keep equipment operating at peak performance.

“We don’t want any of our customers worrying about their hardware after we leave,” Hill says. “So we install, provision, and test the equipment, but we also maintain it 24/7/365. If any hardware fails, we’re going to replace it and it’s not going to cost you anything extra.”

(Side note: Buckeye Mountain guarantees connectivity, or your money back.)

Although some field and IT leaders may be tempted to seek out lower-cost infrastructure solutions that offer greater short-term impact, this approach carries long-term consequences.

“A lot of times, the reason these companies are coming to us now is because, 10 or 15 years ago, someone implemented a cheap system that the terminal quickly outgrew,” says Hill. “So it’s about trying to help the prospect understand that our infrastructure is not only better, but it’s probably going to be cheaper in the long run.”

2. When we need to talk to an expert, who should we call?

Rail and marine facilities need more than new technology. They need accountability and expert support when problems arise.

Whether you’re dealing with technical issues, onboarding difficulties, network performance concerns, or other challenges, you need full confidence that you can quickly connect with an expert offering guidance and other resources.

3. What is the long-term benefit of investing in quality wireless infrastructure?

Faced with surprising costs related to new infrastructure investments, some field and IT leaders may be tempted to seek out lower-cost infrastructure solutions that offer greater short-term impact, even at the expense of more pronounced long-term benefits.

“A lot of times, the reason they’re coming to us now is because, 10 or 15 years ago, some network admin implemented a cheap system that they quickly outgrew,” says Hill. “So it’s about trying to help the prospect understand that our infrastructure is not only better, but it’s probably going to be cheaper in the long run.”

4. What future costs will this infrastructure help me avoid?

On the subject of cost: when evaluating wireless infrastructure options, take some time to get more granular about the long-term outlook for this investment, especially when it comes to future cost avoidance.

If better battery systems and backup power reduce outages and downtime, for example, you can avoid the opportunity cost of stalled operations. Meanwhile, faster and more reliable connectivity can accelerate operations and realize new efficiencies across your facility workflows, controlling costs and supporting greater revenue generation. Aligning your network and technology plans can help you scale effectively. As you adopt new technologies like AI, remote operations, and high-resolution cameras, you’ll need a strong network to support them.

5. Can you point to success stories for projects similar to ours?

Satisfied customers are a strong marker of credibility. If an infrastructure provider can point to successful past projects involving similar needs and challenges to your own facility, you can have more confidence in their ability to deliver for your property.

“One thing we will never do is grow into a space without first being experts or investing in those who are already experts in that space,” says Dunnell. “We understand that we can’t go in there expecting to be taken seriously. And we recognize that if we did behave that way, we would not be acting in the best interest of our customer.”

There’s No Need to Worry About Your Wireless Connection

In dynamic outdoor environments, conventional wireless connectivity can change like the weather. Some days you’ll get sun, other days storms.

But field operations can’t function with unpredictable connectivity. They need consistent, reliable coverage, as well as high throughputs to keep their workflows humming.

That’s why we created our Rapid Deploy family of products. And, with Buckeye Mountain’s commitment to excellent delivery and expert support, we do everything we can to help our customers maximize the value of their wireless investment.

Don’t let a poor wireless connection drag down your operations. Find out how Buckeye Mountain can help you design and deploy an infrastructure tailored to your environment’s unique needs.

Ready? Let’s talk.

The Buckeye Mountain Story

How Buckeye Mountain is Bridging the Gap Between Operations and Technology

Efficiency, coordination, and safety are all central to the daily operations of any rail yard or terminal. But field operations leaders must address and overcome a wide range of operational challenges impacting their daily workflows and processes:

- High turnover rates limit the knowledge base and performance of rail yard staff.

- New technologies adopted to streamline operations can face resistance from frontline workers—and technological challenges in implementing these solutions can further impact their functionality and ROI.

- When operations leaders are tasked with supervising multiple sites, they often struggle to manage inventory, asset tracking, and resource allocation at scale and across multiple sites.

Three founders recognized the negative impact these operational challenges had across the rail industry. More importantly, they saw an opportunity to transform rail yard operations by bringing together their experience in the industry and technology-forward approach to create Buckeye Mountain more than fifteen years ago.

“Our intent from the start was to try and truly understand the problem to be solved, and then leverage streamlined processes and technology to solve it,” says Greg Dunnell, Principal at Buckeye Mountain. “And if it didn’t exist, we innovated and built it side by side with our customers until it met their needs.”

“That was the origin of Buckeye. We took all of those technological elements – software, hardware and wireless – and tried to put them in one place to make it easier for our intermodal/railroad customers. One hand to shake for all your technical solution needs.”

Today, Buckeye Mountain is a leading provider of end-to-end solutions for the intermodal and rail industries, providing rugged hardware, customized software, wireless network infrastructure, and robust tech support and operations consulting to rail and intermodal yards around the country.

In the past, all of these challenges were compounded with the lack of support of resource management software and solutions to alleviate this manual burden.

The Buckeye Mountain story

Most rail yards are operated by a patchwork of contracted vendors handling gate control, inventory management, safety and other critical aspects of operations.

Add to that the dozen or some companies working on the railroad itself—with each organization focused on specialized infrastructure such as locomotives, rail cars, and intermodal transportation—and it’s easy to see how the fragmentation of rail yard operations presents a challenge when trying to streamline workflows, implement operationally vital technology tools and maintain consistently efficient processes.

Buckeye Mountain was founded to address these limitations, delivering value to its customers by using technology to unify, coordinate, and optimize rail yard operations.

“When we formed in 2006, we were focused on using the ‘three-legged stool’ of software, wireless, and mobile devices to help our railroad customers get the most out of their technology investments,” says Dunnell. “We’ve continued to grow, transitioning from that starting point to where we are today.”

Leadership focused the organization’s resources and efforts on becoming an unrivaled technology leader in the rail industry.

“We believed we would gain enormous credibility by taking time to understand this market,” says Matt Hunter, Principal of Sales and Operations at Buckeye. “We made a very conscious effort to be laser-focused on our customers’ needs.”

Says Dunnell: “Early on we found ourselves competing most directly with our customers themselves because they had set up organizations within the railroads to provide these critical services. But because we were able to focus on this one specialty that aligned with our core competency, we were able to deliver more cost effective results that exceed our customer’s expectations.

“That’s how we won over our first customers—and we continued growing from there.”

A problem-solver for intermodal supply chain

As the volume of rail-based intermodal transportation has increased in recent years—fueled by the growth of e-commerce and rail’s superior cost-efficiencies over truck-based transport, among other factors—Buckeye Mountain has expanded its investments into solutions tailored specifically to the intermodal space.

Intermodal transportation presents a different set of challenges than railroad operations. Since intermodal shipping containers are moved by trucks, trains, ships, and cranes, and can be stacked several units high for compact storage, Wi-Fi connectivity and communication becomes more complex. Likewise, the technology deployed into these environments must be durable enough to withstand rugged conditions.

Buckeye Mountain addressed these limitations by developing new mobility solutions tailored to the unique needs of intermodal transport.

“We have a patented, unique way of deploying, maintaining, and guaranteeing wireless connectivity inside of those very difficult intermodal environments,” says Dunnell. “We solve the problems that others can’t because we live in those environments 100 percent of the time.”

Expanding into marine operations

In recent years, Buckeye Mountain’s core competencies as a rail and intermodal solutions provider have served as a bridge connecting the company to inland and port customers.

Many of the core offerings utilized by intermodal customers—including Buckeye’s Rapid Deploy Wi-Fi coverage solutions and its “boots on the ground” approach—are relevant to the pain points commonly faced by marine terminal operations. With supply chain operations encompassing multiple modes of transportation, the technology used to manage and streamline those operations is blurring the lines of differentiation that have historically kept them separate.

For Buckeye Mountain, this isn’t about “blurring the lines”—it’s about leveraging proven technologies in new environments.

“While we may move into a new area of the business, we’re able to leverage things we’ve done in the past to bridge that gap,” says Matt Gretz, Principal of IT & Software Development at Buckeye Mountain. “Seventy percent of the new solution might be something we’ve already done for a different project, so our customers trust us to take on new challenges.”

Buckeye delivers the hardware, the software, and the technical support

Successful digital transformation requires an end-to-end approach. That’s why Buckeye Mountain isn’t simply a solutions vendor, with a consultative approach with each customer, identifying solutions to address their most urgent pain points and ensuring success through proper implementation, onboarding, and ongoing support.

Here are three key cornerstones of that customer-centric approach:

Wireless network infrastructure

Traditional wireless providers prioritize consumer needs over the vital connectivity required by rail terminals. Buckeye Mountain equips rail, intermodal, and marine operations with reliable connectivity delivered through a patented, unique infrastructure built for challenging intermodal outdoor environments.

The Rapid Deploy family of products, including RapidSky, provides consistent Wi-Fi coverage even in difficult settings such as high-stack intermodal areas and marine ports. These custom-built solutions can overcome environmental interference, optimize signal patterns and connectivity, and monitor Wi-Fi connection quality for enhanced connectivity and a better user experience.

Boots on the ground

High turnover rates, combined with an underutilization of new technologies and tools, can undercut the impact and value of new technology investments. Buckeye is changing this status quo by offering operator services that staff terminals with Buckeye personnel who can serve as adept operators and knowledgeable custodians of this new technology.

This “boots on the ground” approach is Buckeye’s solution to reducing the impact of high staff turnover and the expertise gaps common among operations teams, ensuring seamless operation of these new technology investments.

Rail, intermodal, and marine logistics expertise

Buckeye’s field support services are designed to provide comprehensive, hands-on assistance during critical technology implementations and ongoing operations.

During TOS go-live events, for example, Buckeye supplements client resources with rugged, field-ready personnel who can train operating personnel, manage installations and logistics while providing post-implementation troubleshooting. They also offer staffing and operator services to provide skilled personnel for TechOps roles such as load planners, gate clerks, and field maintenance workers to terminals with long-term contracts.

Transform your operations with fit-for-purpose technology

Technology holds the key to streamlining workloads and realizing cost-efficiencies across rail, intermodal, and marine operations. But operations personnel can’t simply be handed a new tool and documentation and be expected to get the most out of it.

They need to be trained and truly understand the value of new technology investments—and to take ownership over their implementation.

That’s where Buckeye Mountain sets itself apart.

“As we are expanding we are hitting more competition,” says Dunnell. “But what we are trying to do, very deliberately, is to do things a little bit differently in the best interest of our customer. We want to expand the role of the operator to make them the custodians of the operationally critical technology tools being deployed.”

It’s time to stop drawing a line between operations and technology. Buckeye Mountain can help bring them together for a seamless fit that streamlines your workflows and maximizes the return on your technology investment.